当前位置:KHC进口高速钨钢铣刀首页 > 产品中心

> 高硬度钨钢铣刀 > 强力高效率2刃钨钢平底深沟铣刀

产品名称:强力高效率2刃钨钢平底深沟铣刀

- 所属分类:高硬度钨钢铣刀

- 产品型号:KHA235P

材质:0.2μ

涂层:TISIN

螺旋角度:35

适合加工硬度:HRC62以下

单位:mm

进口高速钨钢铣刀领导品牌在德国已经38年

涂层:TISIN

螺旋角度:35

适合加工硬度:HRC62以下

单位:mm

订购热线:400-6848-288

应用范围

“KHC”是德国整体硬质合金铣刀品牌,使用世界上最先进的德国、瑞士研磨设备,采用欧洲高品质的钨钢棒材及搭配世界一流的镀层技术,造就了KHC钨钢铣刀高速、高效率、高硬度及高性价比的金属切削刀具。KHA235P是高速高硬度2刃平底钨钢铣刀,适合加工62度以下材料加工。目前“KHC钨钢铣刀”主要应用模具机械等加工行业。

产品规格

产品参数下载

| 序号 | 品名 | Model NO. 产品编号 | Dia. 刃径 | Flute Length 刃长 | Shank Dia. 柄径 | Overall Length 全长 | Effective Length 有效长 | Neck Dia 首下径/颈径 |

| 1 | KHA235P | K300200201 | 0.2 | 0.3 | 4 | 50 | 1 | 0.18 |

| 2 | K300200202 | 0.2 | 0.3 | 4 | 50 | 2 | 0.18 | |

| 3 | K300200301 | 0.3 | 0.4 | 4 | 50 | 1 | 0.26 | |

| 4 | K300200302 | 0.3 | 0.4 | 4 | 50 | 2 | 0.26 | |

| 5 | K300200303 | 0.3 | 0.4 | 4 | 50 | 3 | 0.26 | |

| 6 | K300200401 | 0.4 | 0.5 | 4 | 50 | 1 | 0.36 | |

| 7 | K300200402 | 0.4 | 0.5 | 4 | 50 | 2 | 0.36 | |

| 8 | K300200403 | 0.4 | 0.5 | 4 | 50 | 3 | 0.36 | |

| 9 | K300200404 | 0.4 | 0.5 | 4 | 50 | 4 | 0.36 | |

| 10 | K300200405 | 0.4 | 0.5 | 4 | 50 | 5 | 0.36 | |

| 11 | K300200406 | 0.4 | 0.5 | 4 | 50 | 6 | 0.36 | |

| 12 | K300200408 | 0.4 | 0.5 | 4 | 50 | 8 | 0.36 | |

| 13 | K300200410 | 0.4 | 0.5 | 4 | 50 | 10 | 0.36 | |

| 14 | K300200502 | 0.5 | 0.6 | 4 | 50 | 2 | 0.46 | |

| 15 | K300200503 | 0.5 | 0.6 | 4 | 50 | 3 | 0.46 | |

| 16 | K300200504 | 0.5 | 0.6 | 4 | 50 | 4 | 0.46 | |

| 17 | K300200505 | 0.5 | 0.6 | 4 | 50 | 5 | 0.46 | |

| 18 | K300200506 | 0.5 | 0.6 | 4 | 50 | 6 | 0.46 | |

| 19 | K300200508 | 0.5 | 0.6 | 4 | 50 | 8 | 0.46 | |

| 20 | K300200510 | 0.5 | 0.6 | 4 | 50 | 10 | 0.46 | |

| 21 | K300200602 | 0.6 | 0.7 | 4 | 50 | 2 | 0.55 | |

| 22 | K300200603 | 0.6 | 0.7 | 4 | 50 | 3 | 0.55 | |

| 23 | K300200604 | 0.6 | 0.7 | 4 | 50 | 4 | 0.55 | |

| 24 | K300200605 | 0.6 | 0.7 | 4 | 50 | 5 | 0.55 | |

| 25 | K300200606 | 0.6 | 0.7 | 4 | 50 | 6 | 0.55 | |

| 26 | K300200702 | 0.7 | 0.8 | 4 | 50 | 2 | 0.65 | |

| 27 | K300200704 | 0.7 | 0.8 | 4 | 50 | 4 | 0.65 | |

| 28 | K300200706 | 0.7 | 0.8 | 4 | 50 | 6 | 0.65 | |

| 29 | K300200708 | 0.7 | 0.8 | 4 | 50 | 8 | 0.65 | |

| 30 | K300200710 | 0.7 | 0.8 | 4 | 50 | 10 | 0.65 | |

| 31 | K300200802 | 0.8 | 1 | 4 | 50 | 2 | 0.75 | |

| 32 | K300200804 | 0.8 | 1 | 4 | 50 | 4 | 0.75 | |

| 33 | K300200806 | 0.8 | 1 | 4 | 50 | 6 | 0.75 | |

| 34 | K300200808 | 0.8 | 1 | 4 | 50 | 8 | 0.75 | |

| 35 | K300200810 | 0.8 | 1 | 4 | 50 | 10 | 0.75 | |

| 36 | K300200812 | 0.8 | 1 | 4 | 50 | 12 | 0.75 | |

| 37 | K300201002 | 1 | 1.2 | 4 | 50 | 2 | 0.95 | |

| 38 | K300201003 | 1 | 1.2 | 4 | 50 | 3 | 0.95 | |

| 39 | K300201004 | 1 | 1.2 | 4 | 50 | 4 | 0.95 | |

| 40 | K300201005 | 1 | 1.2 | 4 | 50 | 5 | 0.95 | |

| 41 | K300201006 | 1 | 1.2 | 4 | 50 | 6 | 0.95 | |

| 42 | K300201008 | 1 | 1.2 | 4 | 50 | 8 | 0.95 | |

| 43 | K300201010 | 1 | 1.2 | 4 | 50 | 10 | 0.95 | |

| 44 | K300201012 | 1 | 1.2 | 4 | 50 | 12 | 0.95 | |

| 45 | K300201014 | 1 | 1.2 | 4 | 50 | 14 | 0.95 | |

| 46 | K300201016 | 1 | 1.2 | 4 | 50 | 16 | 0.95 | |

| 47 | K300201018 | 1 | 1.2 | 4 | 50 | 18 | 0.95 | |

| 48 | K300201020 | 1 | 1.2 | 4 | 50 | 20 | 0.95 | |

| 49 | K300201206 | 1.2 | 1.5 | 4 | 50 | 6 | 1.15 | |

| 50 | K300201208 | 1.2 | 1.5 | 4 | 50 | 8 | 1.15 | |

| 51 | K300201210 | 1.2 | 1.5 | 4 | 50 | 10 | 1.15 | |

| 52 | K300201212 | 1.2 | 1.5 | 4 | 50 | 12 | 1.15 | |

| 53 | K300201504 | 1.5 | 1.8 | 4 | 50 | 4 | 1.45 | |

| 54 | K300201506 | 1.5 | 1.8 | 4 | 50 | 6 | 1.45 | |

| 55 | K300201508 | 1.5 | 1.8 | 4 | 50 | 8 | 1.45 | |

| 56 | K300201510 | 1.5 | 1.8 | 4 | 50 | 10 | 1.45 | |

| 57 | K300201512 | 1.5 | 1.8 | 4 | 50 | 12 | 1.45 | |

| 58 | K300201514 | 1.5 | 1.8 | 4 | 50 | 14 | 1.45 | |

| 59 | K300201516 | 1.5 | 1.8 | 4 | 50 | 16 | 1.45 | |

| 60 | K300201810 | 1.8 | 2 | 4 | 50 | 10 | 1.75 | |

| 61 | K300201814 | 1.8 | 2 | 4 | 50 | 14 | 1.75 | |

| 62 | K300201818 | 1.8 | 2 | 4 | 50 | 18 | 1.75 | |

| 63 | K300202006 | 2 | 2.5 | 4 | 50 | 6 | 1.92 | |

| 64 | K300202008 | 2 | 2.5 | 4 | 50 | 8 | 1.92 | |

| 65 | K300202010 | 2 | 2.5 | 4 | 50 | 10 | 1.92 | |

| 66 | K300202012 | 2 | 2.5 | 4 | 50 | 12 | 1.92 | |

| 67 | K300202014 | 2 | 2.5 | 4 | 50 | 14 | 1.92 | |

| 68 | K300202016 | 2 | 2.5 | 4 | 50 | 16 | 1.92 | |

| 69 | K300202018 | 2 | 2.5 | 4 | 50 | 18 | 1.92 | |

| 70 | K300202020 | 2 | 2.5 | 4 | 50 | 20 | 1.92 | |

| 71 | K300202508 | 2.5 | 3 | 4 | 50 | 8 | 2.4 | |

| 72 | K300202512 | 2.5 | 3 | 4 | 50 | 12 | 2.4 | |

| 73 | K300202516 | 2.5 | 3 | 4 | 50 | 16 | 2.4 | |

| 74 | K300202520 | 2.5 | 3 | 4 | 50 | 20 | 2.4 | |

| 75 | K300203010 | 3 | 3.5 | 6 | 50 | 10 | 2.85 | |

| 76 | K300203012 | 3 | 3.5 | 6 | 50 | 12 | 2.85 | |

| 77 | K300203016 | 3 | 3.5 | 6 | 50 | 16 | 2.85 | |

| 78 | K300203020 | 3 | 3.5 | 6 | 60 | 20 | 2.85 | |

| 79 | K300203025 | 3 | 3.5 | 6 | 60 | 25 | 2.85 | |

| 80 | K300203030 | 3 | 3.5 | 6 | 60 | 30 | 2.85 |

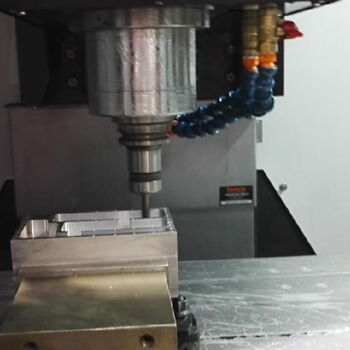

加工效果图

强力高效率2刃钨钢平底深沟铣刀、加工图及外包装图:

上一篇:高硬度2刃钨钢加长柄球头铣刀

下一篇:高硬度强力型2刃深沟钨钢球头铣刀